What are the common OEM manufacturing mistakes that quietly derail even the most promising product launches? For many global buyers, the pitfalls aren’t about creativity or vision—they come from small, early-stage decisions that accumulate into significant setbacks.

After supporting hundreds of B2B brands in the pet product space, one pattern stands out: these mistakes repeat year after year, regardless of company size or experience.

The impact goes far beyond unexpected costs. Costly OEM mistakes can stall product launches, disrupt supply chains, and drain precious time and resources, leaving brands frustrated and behind competitors.

In this guide, you’ll discover the most critical mistakes across the OEM manufacturing process and practical strategies that seasoned buyers use to avoid OEM manufacturing risks, safeguard timelines, and ensure smooth delivery from concept to market.

🔹Phase 1: Design & Early Development🔹

#1 – Common OEM Manufacturing Mistakes During Product Design and R&D

Small design decisions can quietly grow into significant hurdles if not carefully managed. Many brands, despite having innovative ideas, encounter common OEM manufacturing mistakes that could have been avoided with the right early planning.

For a complete understanding of how design choices influence manufacturing success, you can refer to our end-to-end OEM manufacturing process in China, which walks through the workflow from concept to delivery.

OEM Product Development Mistakes That Limit Scalability

Working with an OEM that lacks strong in-house R&D can sharply limit your product’s future potential. Many brands underestimate the value of working with OEM factories capable of:

- Firmware development

- App integration

- Iterative design improvements

💡 You might find it helpful to learn how Petrust® optimizes design for scalable products—contact us for a case study that illustrates real-world results.

Why Common OEM Manufacturing Mistakes Often Start at the R&D Stage

Decisions made in the early stages often ripple throughout the entire manufacturing process:

- Inadequate prototyping

- Unclear specifications

- Overlooked technical feasibility

These missteps frequently manifest as OEM production failures, as documented in a 2025 NIH study on manufacturing and prototyping. Experienced buyers, including Petrust®, emphasize iterative design reviews and collaborative R&D to catch potential issues early, ensuring smoother downstream manufacturing and scalable product development. This approach has proven particularly effective for OEM Automatic Cat Litter Box projects.

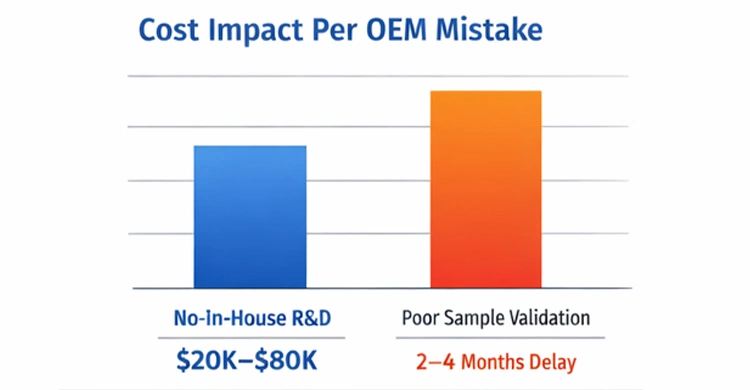

Cost Quantification Table

| Mistake | Typical Cost |

| No in-house R&D | $20,000–$80,000 in redesign and delays |

| Poor sample validation | 2–4 months lost before mass production |

🔹Phase 2: Supplier Selection🔹

#2 – OEM Supplier Selection Mistakes Brands Often Overlook

Choosing the wrong supplier can silently undermine even the best designs. For a structured way to evaluate potential partners, you can refer to key questions for selecting pet production OEMs, helping ensure that your choice supports both quality and scalability.

OEM Supplier Reliability Issues Beyond Price and MOQ

Focusing only on price or minimum order quantities often conceals OEM sourcing risks. Core evaluation points include:

- Production planning and capacity

- Track record and reliability

- Quality management systems

Many global brands working with OEM Automatic Cat Feeder suppliers validate prototypes before scaling to full production, minimizing surprises and maintaining timelines.

OEM Factory Communication Problems That Cause Hidden Delays

Misalignment in expectations frequently causes OEM manufacturing delays. Best practices to prevent this include:

- Clear documentation of requirements

- Structured, milestone-based communication

- Regular alignment checkpoints

You might find effective design change communication tips helpful to ensure that expectations stay aligned.

💡 Engaging in early supplier alignment, such as a consultation with Petrust®, can greatly streamline your sourcing process and reduce hidden risks.

🔹Phase 3: Prototype & Sample Testing🔹

#3 – OEM Manufacturing Pitfalls in Prototype and Sample Testing

A methodical, step-by-step approach during prototyping is essential to avoid errors. For a detailed walkthrough, refer to prototype development steps with Chinese OEMs, which outline key processes for validating designs before full-scale production.

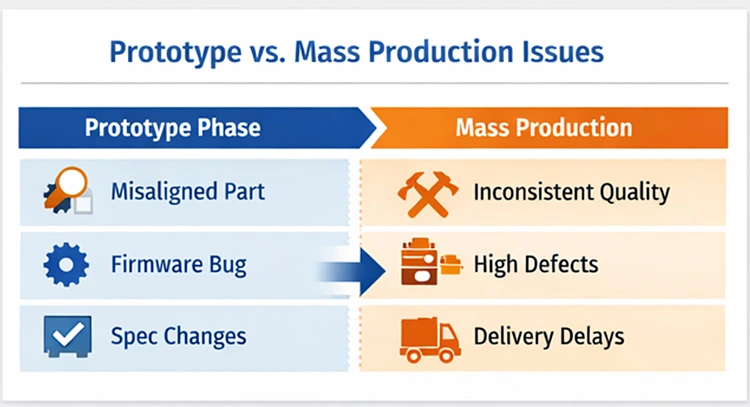

OEM Sample Approval Mistakes That Lead to Mass Production Failure

Approving a prototype alone does not guarantee consistent results in mass production. Alignment between the prototype and mass production process is critical.

For example, one buyer approved a prototype for a smart cat feeder, but batch production revealed hopper misalignment, leading to 10% waste. Iterative reviews and QC checks with Petrust® prevented these mistakes from repeating.

Why Prototype Success Doesn’t Guarantee Production Consistency

Even a flawless prototype can hide common OEM manufacturing issues during batch production. Variations in assembly, materials, or processes can cause delays, increased costs, or product inconsistencies. Paying careful attention to prototyping and early QC helps brands safeguard launches and maintain reliability.

🔹Phase 4: Quality Control & Inspection🔹

#4 – Common OEM Manufacturing Mistakes in Quality Control and Inspection

Maintaining consistent product quality is one of the most frequent challenges in OEM partnerships. Many brands encounter delays or defects simply because inspection steps were overlooked.

For actionable guidance, you can refer to in-process QC checkpoints for OEMs, which outline strategies to reduce OEM quality problems and keep production running smoothly.

OEM Quality Control Issues Caused by Incomplete Inspection Planning

Skipping pre-production, in-line, or pre-shipment checks leads to OEM quality problems. A structured approach helps prevent small errors from becoming costly failures:

- Pre-production inspection

- In-line inspection

- Pre-shipment inspection

Third-Party Inspection vs In-House QC: Common Misunderstandings

Relying only on third-party audits often creates a false sense of security. ISO’s conformity assessment framework emphasizes that internal QC processes are essential for catching issues before they escalate.

Top OEMs, such as Petrust®, combine in-process QC with independent third-party audits to proactively detect defects. You might find their workflow for OEM Cat Water Fountain particularly helpful as a real-world example.

💡 You can also see how Petrust® maintains QC excellence across all production lines—schedule a consultation to learn more.

🔹Phase 5: Certification & Compliance🔹

#5 – Common OEM Manufacturing Problems with Certification and Compliance

Certification and regulatory compliance are critical checkpoints for global buyers. Reviewing essential certifications for pet OEMs early helps prevent costly shipping delays and legal setbacks.

OEM Compliance Risks Related to CE, FCC, and Regional Regulations

Using certificates incorrectly can halt shipments and jeopardize brand reputation. According to official EU guidelines on CE marking requirements, manufacturers must meet strict documentation, testing, and quality standards to ensure compliance.

Why Certificate Ownership Matters More Than Buyers Expect

It’s not enough for a manufacturer to claim compliance—they must own or provide valid certificates. Doing so helps avoid global OEM sourcing problems and regulatory penalties while keeping your product launch on track.

🔹Phase 6: Mass Production & Scaling🔹

#6 – Common OEM Manufacturing Mistakes in Mass Production and Scaling

Efficient scheduling and realistic capacity planning are the backbone of a successful OEM project. Referencing optimized OEM scheduling & lead time practices can guide buyers toward smoother production cycles and predictable delivery timelines.

OEM Mass Production Risks When Scaling Too Fast

Expanding production without validating capacity often leads to OEM manufacturing delays and inconsistent product quality. Strategic scaling prevents last-minute surprises and protects your brand’s reputation.

OEM Lead Time Delays Caused by Unrealistic Capacity Planning

Without realistic planning, delivery schedules slip and customer satisfaction suffers. Strong OEM production planning ensures every batch meets quality expectations while staying on schedule.

💡 You might find it helpful to discover how Petrust® supports seamless mass production—explore solutions with Petrust® designed to keep your OEM projects reliable and efficient.

🔹Phase 7: OEM in China🔹

#7 – OEM Manufacturing Mistakes in China: What Global Buyers Should Know

Navigating OEM manufacturing in China comes with its own set of nuances. Many global buyers encounter unexpected costs or delays simply because local practices differ from what they’re used to.

You can refer to our guide to finding trustworthy OEM factories in China for practical advice on selecting reliable partners and understanding standard operating procedures.

Structural Differences Between Chinese OEM Factories and Trading Companies

Recognizing the distinction between a factory and a trading company helps prevent hidden costs, misaligned expectations, and communication bottlenecks.

A factory offers direct control over production timelines, quality, and R&D capabilities, while trading companies may provide convenience but add layers of uncertainty—especially when it comes to common OEM manufacturing mistakes that occur without proper oversight.

🔹Phase 8: Pre-Shipment Last Defense🔹

#8 – How to Avoid Common OEM Manufacturing Mistakes Before Shipping

The final stage before shipment is your last line of defense. Utilizing a pre-shipment quality verification checklist can help catch errors before products leave the factory, protecting your brand from costly surprises and ensuring that OEM quality inspection standards are met.

Final Checks That Prevent Common OEM Manufacturing Mistakes Before Delivery

Even minor oversights at this stage can lead to major headaches. Thorough pre-shipment steps include:

- Conducting full OEM quality inspections for consistency

- Verifying packaging integrity and labeling accuracy

- Confirming logistics arrangements and shipping documentation

Process Comparison

| Mistake | Correct OEM Manufacturing Process |

| Skipping QC | Pre-production → In-line → Pre-shipment inspections |

| Unverified sample | Prototype validation aligned with production |

| Choosing cheapest supplier | Evaluate OEM suppliers for reliability, capacity, certifications |

🔹Buyer Checklist🔹

To help global buyers stay proactive and minimize risks, keep this checklist handy:

- Key questions to ask OEMs before engagement

- Critical documents to request from factories

- Red flags to watch for in global OEM sourcing

- Verification steps for overseas OEM suppliers

This checklist is highly practical for B2B buyers and easy to share or bookmark for ongoing sourcing needs.

💡 For a more detailed version, you can download or request a full buyer checklist PDF from Petrust®, providing actionable steps to prevent common OEM manufacturing mistakes and ensure smooth production and delivery.

Conclusion

Many common OEM manufacturing mistakes are not caused by lack of creativity—they often arise from systemic capability mismatches between brand expectations and factory capabilities.

Opting for the cheapest supplier rarely mitigates risk; what truly matters is a comprehensive understanding of the OEM manufacturing in China process, rigorous supplier verification, and structured QC and production planning.

Partnering with experienced manufacturers and following a disciplined approach helps avoid OEM manufacturing risks, minimize OEM production failures, and maintain consistent product quality.

Brands looking for reliability and full-service OEM support may find it helpful to consider Petrust®, which integrates end-to-end design, production, quality control, and compliance expertise, providing predictable outcomes for global product launches.

You can also take a closer look at our full range of OEM automatic cat litter box, cat feeder, and cat water fountain solutions to understand how Petrust® supports streamlined product launches while ensuring high-quality results every time.

The most important takeaway is that investing in prevention early—through careful prototyping, supplier evaluation, and QC planning—saves both time and money, helping your products reach the market on schedule and at the quality your customers expect.

FAQ: Common OEM Manufacturing Mistakes

1. How long does it take to validate a prototype for OEM cat products?

Prototype validation typically takes 4–6 weeks, depending on product complexity and the number of iterative testing cycles. Paying attention to every stage early helps prevent downstream OEM production failures.

2. What certifications should I request from my OEM factory?

CE, FCC, and FDA certifications are standard for global shipments. Ensuring your OEM holds valid, up-to-date documents is critical to avoid costly OEM mistakes and delays.

3. Which QC checkpoints help prevent common OEM manufacturing mistakes?

The most effective quality control points include:

- Pre-production inspections

- In-line production monitoring

- Pre-shipment audits

These steps are crucial for catching issues before they affect a full batch, reducing rework and protecting your brand reputation.

4. What is the most frequent mistake brands make during OEM supplier selection?

Many brands focus only on price or MOQ while overlooking production capacity, track record, and quality systems. Overlooking these factors is one of the most frequent OEM sourcing risks.

5. How can working with Petrust® reduce OEM risks?

Petrust® combines integrated R&D, quality control, regulatory compliance, and mass production oversight. This holistic approach helps brands avoid common OEM manufacturing mistakes while ensuring consistency across multiple product lines.

6. What are the most common prototyping errors that affect production?

Misaligned parts, incomplete firmware testing, and unclear specifications often result in batch inconsistencies. Iterative prototype reviews and collaboration with experienced OEMs are key to smoothing this process.

7. Which visual tools help monitor QC effectively?

Process checklists, workflow diagrams, and milestone dashboards enhance oversight and reduce OEM manufacturing risks, making it easier to track progress and quickly address deviations.

8. How does Petrust® ensure mass production consistency?

Through rigorous capacity validation, iterative QC cycles, and a combination of in-house and third-party inspections, Petrust® helps maintain high-quality standards and minimizes OEM production failures across large-scale orders.