Are you curious how smart pet fountain manufacturing trends in 2026 are reshaping the way pet brands design and deliver hydration solutions? Modern pet owners expect more than just flowing water—they want reliability, safety, and innovation in every fountain. For global buyers, understanding these shifts is no longer optional; it’s central to creating competitive, scalable product lines.

What’s evolving isn’t just the fountain’s functionality—it’s the entire approach to engineering, sourcing, and scaling for multi-pet households. Behind every high-performing smart pet fountain lies a sophisticated balance of:

- Sensor accuracy and long-term reliability to monitor water flow, detect blockages, and adapt to pet usage patterns

- Connected systems and data handling that support app integration, usage analytics, and remote management

- Sustainable, food-safe materials (eco-friendly pet fountain materials) that meet consumer expectations and global compliance standards

- OEM design decisions that influence cost efficiency, production yield, and regulatory adherence

These factors aren’t just technical details—they define whether a fountain succeeds in the real world or ends up returned due to pump failures, water contamination, or poor durability.

This guide highlights the most relevant smart pet fountain manufacturing trends for 2026, focusing on what truly matters to OEM buyers, product managers, and manufacturing decision-makers rather than marketing buzzwords. You can find insights on leading smart pet fountain OEMs in China helpful for benchmarking potential partners and understanding who is truly capable of delivering quality at scale.

For brands preparing to launch or upgrade their smart pet fountain product lines, the trends and insights in this guide offer a clear roadmap to design, source, and scale products that meet both market expectations and operational realities.

Why Smart Pet Fountain Manufacturing Trends Matter in 2026

For pet brands and global buyers, smart pet fountain manufacturing trends in 2026 are shaping not only product design but also market success. Today’s pet owners expect intelligent pet hydration devices that do far more than simply provide water—they want reliability, safety, and connected experiences.

As consumer demand for smart pet hydration continues to rise, manufacturers are under growing pressure to innovate across materials, sensors, connectivity, and sustainability, a shift highlighted in the American Pet Products Association’s 2025 industry trends report.

The conversation has moved beyond simple sensor upgrades or aesthetic tweaks. These trends intersect with future trends in smart pet products, including:

- Connected pet water fountain design

- Eco-friendly production

- Integrated data analytics

- Connected pet hydration device IoT integration

Brands partnering with OEMs who understand these shifts are positioned to capture market share more reliably than those relying on outdated designs. For guidance on assessing potential partners, you might find how to verify reliable smart pet fountain manufacturers in China helpful.

In short, 2026 is a pivotal year where design, sustainability, and connectivity converge, defining the fountains that will lead the market.

Sensor Technology Trends in Smart Pet Fountain Manufacturing

Behind every smart pet fountain that performs reliably day after day, there is a layer of sensor decisions most end users never see—but OEM buyers and product managers think about constantly.

In smart pet fountain manufacturing trends, sensor technology is no longer just a functional checkbox. It directly shapes product stability, return rates, user trust, and long-term brand reputation.

Designing sensor systems today means balancing real-world pet behavior, frequent cleaning, humid environments, and mass-production consistency—all without driving costs out of control. That’s where the latest shifts in sensor strategy are quietly redefining competitive products.

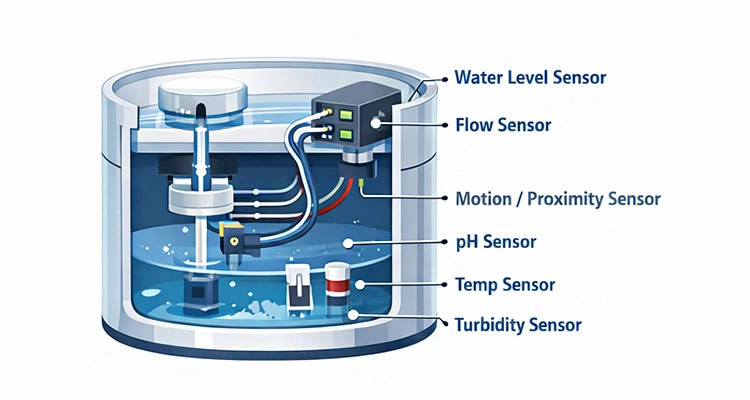

Water Flow & Level Sensors in Smart Pet Fountains

Modern fountains rely heavily on smart pet water fountain sensors to maintain consistent water flow and accurate level detection. These sensors must withstand daily wear, curious pets, and repeated cleaning routines.

Selecting high-quality sensors minimizes false alarms and ensures long-term reliability, as discussed in a 2024 Springer article reviewing IoT application security and architecture challenges—an essential consideration for connected sensor performance. You can also explore latest smart pet fountain sensor innovations for deeper insights.

Motion & Presence Sensors for Pet Drinking Detectio

Tracking when a pet approaches the fountain allows adaptive water dispensing, reducing waste and improving energy efficiency. These automatic pet water fountain technology features also provide behavioral insights that inform smarter hydration management.

Water Quality Monitoring Sensors Within Smart Pet Fountain Manufacturing Trends

Water safety remains a top priority. Advanced smart pet fountain system architecture now integrates pH, temperature, and turbidity sensors to continuously monitor quality.

Such capabilities are increasingly expected by consumers and serve as a clear differentiator in premium intelligent animal care equipment.

Sensor Calibration & Reliability in Mass Production

Maintaining accuracy at scale requires careful planning. OEMs integrate automated calibration routines and quality checks in the pet water fountain production process to prevent inconsistencies and warranty issues.

Key points for mass production quality control:

- Automated calibration protocols for each sensor batch

- Continuous monitoring of sensor drift during assembly

- Testing under variable temperatures and simulated pet use

- Comprehensive documentation for compliance and audits

These steps don’t just protect quality—they protect timelines, margins, and buyer confidence.

Connectivity & IoT Shifts Shaping Smart Pet Fountain Manufacturing Trends

Connectivity has quietly shifted from a “nice-to-have” feature to an expectation that defines product maturity. Within smart pet fountain manufacturing trends, IoT decisions now influence everything from user retention to regulatory exposure and long-term firmware support.

Wi-Fi & Bluetooth Connectivity in Smart Pet Water Fountains

Connectivity is now essential. Smart fountains leverage IoT pet care devices to sync water level, filter status, and pet activity data with mobile apps. Bluetooth provides local control, while Wi-Fi enables cloud integration for global monitoring.

App-Connected Pet Fountains: Data Sync & User Experience

Connected home pet products require seamless app interaction.

Features such as:

- Push notifications for low water

- Filter replacement reminders

- Behavioral analytics

…enhance user experience, encourage brand loyalty, and provide actionable insights for pet owners. You can find IoT and app-connected smart pet fountain design insights helpful for understanding this integration.

Cloud Platforms & Firmware Update Considerations

Cloud integration supports remote monitoring and feature updates. Research on lightweight, secure IoT frameworks published in Scientific Reports demonstrates how cloud-edge systems balance performance and security.

OEMs must design intelligent pet hydration devices with flexible firmware while minimizing downtime during updates.

Cybersecurity & Data Privacy in Connected Pet Devices

As smart fountains collect pet behavior and usage data, smart pet products manufacturing trends increasingly emphasize secure data handling and compliance with global privacy regulations—a crucial factor for OEMs serving international markets.

AI-Driven Design Trends in Smart Pet Fountain Development

What’s driving smart pet fountain manufacturing trends forward in 2026 isn’t flashy AI claims—it’s the very real pressure brands face to deliver smarter hydration without adding complexity, risk, or unnecessary cost.

Buyers today are balancing tighter compliance requirements, rising sustainability expectations, and increasingly educated end users who notice when a product feels thoughtfully engineered.

That’s where AI-driven design quietly reshapes how smart pet fountains are conceived—from how water flows, to how data is processed, to how reliably everything performs inside a compact, water-safe enclosure.

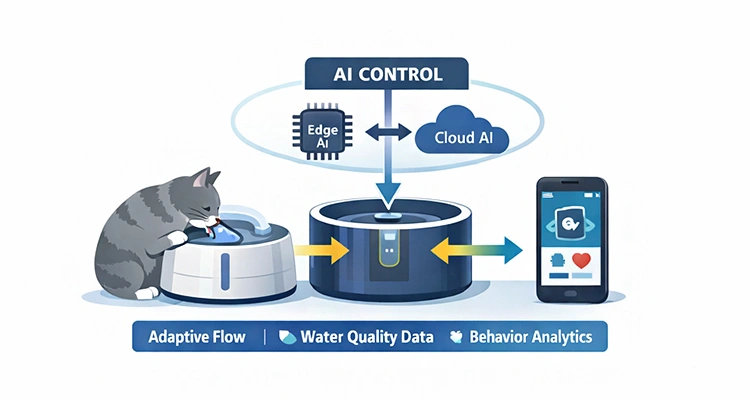

AI Flow Control & Adaptive Water Dispensing

At the core of many next-generation designs is AI-driven flow regulation. Rather than treating water output as a fixed setting, modern systems respond to real pet behavior—helping brands reduce waste while delivering consistent freshness.

To make this easier to evaluate and implement, manufacturers typically break AI flow logic into clear sub-modules:

- Adaptive Flow – Dynamically adjusts water flow based on pet drinking patterns to support steady, comfortable hydration

- Water Waste Reduction – Minimizes over-dispensing, keeping water fresher for longer while conserving resources

- Behavior Analytics Integration – Collects drinking behavior data that can later support owner insights and early health alerts

This modular approach allows OEM buyers to scale intelligence gradually, without overengineering entry-level models.

Pet Drinking Behavior Analytics & Health Insights

Beyond flow control, AI opens the door to meaningful health-related insights. By analyzing usage patterns over time, algorithms can flag dehydration risks or sudden behavioral changes that may signal stress or illness—value-add features that increasingly matter in premium markets.

For brands evaluating how these features translate into real-world manufacturing decisions, you might find AI-driven flow control and pet behavior analytics in smart pet fountain design helpful as a practical reference point.

Edge AI vs Cloud AI Decisions in Smart Pet Fountain Manufacturing Trends

As AI becomes more embedded, manufacturers face a fundamental architectural choice: Edge AI (on-device) or Cloud AI.

In the context of automatic pet water fountain technology, this decision directly impacts latency, energy consumption, and privacy compliance. Edge AI supports faster response times and stronger data privacy, while cloud-based systems enable richer analytics and easier updates.

The right balance often depends on target markets, certification requirements, and long-term maintenance strategy.

AI Model Training & Hardware Limitations

All of these ambitions still operate within physical constraints. Processing power, memory size, heat management, and waterproofing place real limits on what AI models can run reliably.

That’s why successful manufacturers prioritize lean, purpose-built AI models that perform consistently inside compact, water-safe housings—without sacrificing stability over long-term use.

Sustainable Material Choices Redefining Smart Pet Fountain Manufacturing Trends

Alongside smarter electronics, materials are becoming just as strategic. Sustainability is no longer a branding add-on—it’s a sourcing requirement that influences compliance, cost structure, and buyer trust across global markets.

BPA-Free & Food-Grade Plastics for Pet Water Fountains

BPA-free pet fountain production using food-grade plastic pet water fountain materials remains foundational, particularly for brands targeting premium or health-conscious consumers.

Beyond safety, these choices signal long-term reliability and regulatory readiness—qualities B2B buyers actively screen for.

Recycled & Bio-Based Materials in Smart Fountain Design

Momentum is also building around sustainable materials such as recycled plastics and bio-based polymers. When selected correctly, these options reduce environmental impact without compromising durability or finish quality.

Many design teams reference material research from sources like ACS Sustainable Chemistry & Engineering when evaluating viable alternatives.

For a broader view, you might find trending sustainable materials for smart pet fountains useful when planning future product iterations.

Eco-Friendly Manufacturing Processes & Certifications

Material choices only tell part of the story. Eco-friendly pet water fountain manufacturing increasingly integrates energy-efficient production lines, waste reduction systems, and compliance with certifications such as RoHS, CE, PSE (Japan), and RCM (Australia).

Forward-looking projects also consider EPA guidelines for material lifecycle management when mapping long-term sustainability goals.

Key considerations:

- Energy-efficient production methods

- Waste reduction and recycling

- Certifications to meet global compliance

- Cost vs. sustainability trade-offs

Together, these decisions shape not just how a product is made—but how confidently it can be scaled, certified, and trusted in competitive global markets.

Next-Generation Filtration & Water Purification Trends

Water quality has quietly become one of the most scrutinized aspects of smart pet fountain manufacturing trends—and for good reason. Behind every sleek fountain design is a simple expectation from pet owners: the water must stay clean, fresh, and safe day after day, without constant intervention.

For brands and OEM buyers, that expectation translates into deeper questions around filtration architecture, long-term reliability, and regulatory alignment across markets.

As product lifecycles get shorter and consumer trust becomes harder to earn, filtration is no longer a “component choice.” It is a design philosophy that directly shapes user experience, maintenance behavior, and brand reputation.

Multi-Stage Filtration Systems for Smart Pet Fountains

Most next-generation smart fountains now rely on layered filtration structures rather than single-filter solutions. Each layer plays a distinct role in maintaining water integrity throughout continuous circulation:

- Mechanical: removes large particles such as hair and food debris before they circulate through the system

- Chemical: activated carbon or ion exchange materials reduce odors, chlorine, and dissolved contaminants

- Biological: supports safe microbe control in circulating water, helping stabilize long-term water quality

For teams evaluating advanced architectures, you might find next-gen filtration and purification techniques for smart pet fountains helpful when comparing design trade-offs and performance benchmarks.

Activated Carbon, Ion Exchange & UF Filtration

As regulatory scrutiny tightens, filtration material choices are increasingly tied to compliance outcomes.

The combined use of activated carbon, ion exchange resins, and ultrafiltration membranes allows manufacturers to consistently meet strict compliance standards for pet water devices, while also improving taste and clarity from the end user’s perspective.

From an OEM standpoint, these combinations also reduce post-sale issues related to odor complaints, residue buildup, and inconsistent water flow—small problems that often become costly at scale.

Filter Lifespan Optimization & Replacement Design

Ease of maintenance has a direct impact on how products are reviewed, returned, or recommended. Smart fountain designs now emphasize timely replacement indicators that remove guesswork for pet owners and reduce misuse caused by overdue filters.

This seemingly small design decision often leads to measurable improvements in customer satisfaction, fewer support tickets, and more predictable consumables revenue for brands.

Water Safety Standards & Testing Requirements

Filtration performance alone is not enough without verified safety. OEM manufacturers must validate water purity through internationally recognized standards, including NSF/ANSI, EU regulations, PSE, RCM, to ensure authoritative compliance across regions.

For teams navigating cross-market certification pathways, CE and global compliance verification for pet water fountains can offer clarity on how these standards intersect during product approval and shipment preparation.

OEM Design Implications of Smart Pet Fountain Manufacturing Trends

While filtration defines water safety, OEM design decisions determine whether a product can scale reliably, ship consistently, and maintain quality across thousands—or millions—of units. This is where smart pet fountain manufacturing trends move from theory into execution.

Design for Manufacturability (DFM) in Smart Fountains

Embedding OEM considerations early in the design phase reduces downstream risk. Thoughtful DFM planning lowers tooling revisions, stabilizes yields, and supports consistent quality during mass production.

At Petrust®, rigorous DFM processes help ensure products remain scalable and reliable across global markets, even as regulatory and material requirements evolve.

Teams looking to refine their own designs may benefit from a conversation with our engineers—contact our OEM team for a consultation or sample review to identify manufacturability opportunities early.

For a broader production perspective, end-to-end OEM manufacturing processes in China provides useful context.

Component Sourcing & Supply Chain Stability

Reliable sourcing has become a strategic advantage rather than a back-end function. Electronics, sensors, and food-safe plastics must now meet both performance expectations and sustainability goals.

Many manufacturers are shifting toward long-term supplier partnerships to reduce volatility and environmental impact simultaneously.

For brands preparing larger production runs, high-capacity smart cat fountain sourcing solutions may offer practical insights into balancing scale, cost control, and supplier resilience.

Quality Control & Functional Testing in Mass Production

As production scales, maintaining sensor accuracy, connectivity stability, and consistent water quality becomes increasingly complex. Robust QA systems—covering functional testing, water flow validation, and electronic stress testing—are essential to protect both product performance and brand credibility.

Compliance, Certification & Global Market Requirements

Market access ultimately depends on compliance. Alignment with CE, FCC, FDA, PSE, RCM standards—combined with eco-friendly manufacturing practices—signals professionalism and long-term commitment to buyers and distributors alike.

For teams seeking a consolidated view, comprehensive smart cat water fountain certification guide can serve as a practical reference when planning certifications across multiple regions.

What These Smart Pet Fountain Manufacturing Trends Mean for OEM Buyers

For OEM buyers, these shifts are not abstract industry talk—they surface in real conversations about delayed launches, certification surprises, unstable sensors, or sustainability claims that don’t hold up under scrutiny.

Paying close attention to smart pet fountain manufacturing trends helps turn those pain points into design and sourcing advantages.

These trends directly influence how brands approach:

- Designing connected pet water fountain design solutions that feel intuitive to end users while remaining stable, secure, and scalable on the manufacturing side

- Leveraging smart pet fountain OEM manufacturing expertise to shorten development cycles and avoid costly redesigns late in the process

- Choosing materials and production methods that balance BPA-free pet fountain production, long-term durability, and sustainability commitments

- Reducing uncertainty in the pet water fountain production process through structured quality controls, compliance validation, and supplier audits that go beyond surface-level checks

Taken together, these decisions shape more than a single product launch—they define how resilient and adaptable a product line will be as the market continues to mature.

Many OEM teams find it helpful to align internal planning with broader industry signals, including insights reflected in the APPA 2025 State of the Industry Report, which highlights how technology adoption and sustainability expectations are converging.

As 2026 approaches, working with OEM partners who can integrate AI capabilities, ensure sensor reliability, and apply sustainable materials at scale becomes less of a differentiator—and more of a baseline requirement.

FAQ: Smart Pet Fountain Manufacturing

1. How to ensure sensor reliability in multi-cat households?

Sensor performance often breaks down not in labs, but in real homes. Reliability improves when calibration protocols account for overlapping usage, simulated stress testing mirrors real-world behavior, and automated QA checks are embedded early rather than added as a final step.

2. Which sustainable materials meet global certification standards?

OEMs increasingly rely on food-grade, BPA-free pet water fountain production materials, recycled polymers, and bio-based plastics that comply with CE, FCC, PSE, RCM, and EPA requirements. The key is validating material traceability alongside certifications, not treating them as separate tasks.

3. Should AI processing be on-device or cloud-based?

Edge AI supports faster response times and stronger privacy control, while cloud-based AI enables deeper analytics and remote updates. Most successful designs strike a balance based on usage scenarios, connectivity reliability, and long-term data strategy.

4. How can OEMs minimize production risks?

Production risks tend to surface late when early decisions are rushed. Integrating DFM at concept stage, conducting supplier audits, running functional testing across pilot batches, and verifying certifications before mass production significantly lowers exposure.

Conclusion

Smart pet fountain manufacturing is moving faster—and becoming more interconnected—than many OEM buyers initially expect.

Advances in smart pet water fountain sensors, alongside growing demand for eco-friendly pet water fountain manufacturing, are reshaping how products are designed, validated, and brought to market.

Every decision around design, connectivity, AI integration, and sustainable materials feeds into a broader equation that determines not only compliance, but long-term brand credibility.

As competitive pressure increases, the companies that internalize these smart pet fountain manufacturing trends will be the ones setting the standard for quality, innovation, and consumer trust—well beyond 2026.