Could a clear comparison of litter robot vs Chinese litter box manufacturers reveal the smartest path for your brand in 2026? For many importers and private-label entrepreneurs, Litter Robot still represents the gold standard in premium self-cleaning litter boxes.

Its reliability and automation are well known—but the high price, limited OEM flexibility, and rigid supply chain often leave businesses weighing whether scaling private-label operations is truly feasible.

At the same time, Chinese litter box manufacturers for OEM have rapidly closed the gap. Many now rival international brands in features, engineering, and durability while offering comprehensive OEM / ODM manufacturing services.

This flexibility allows private-label brands to customize, innovate, and scale efficiently without compromising quality. For those looking to launch or grow their private-label lines, resources like reliable Chinese litter box OEMs can be helpful in identifying partners capable of meeting both volume and compliance requirements.

The essential question for 2026 isn’t which product is inherently “better.” It’s: Which option actually makes sense for your business model in 2026? Understanding cost structures, production flexibility, and risk management can mean the difference between smooth market entry and unexpected setbacks.

This article provides global buyers with a structured approach to answer that question, combining cost analysis, manufacturing insights, and risk evaluation to help you confidently choose between premium brands and capable Chinese manufacturers—so you can build a private-label strategy that scales successfully.

Litter Robot vs Chinese Litter Box Manufacturers: Which Option Fits Your Business in 2026?

Decision Map for Consumers, Brands, and Distributors

Global buyers approach the market differently depending on their priorities and business model:

- Consumers: Litter Robot offers a ready-to-use, reliable solution.

- Private Label Brands: Chinese OEMs provide flexible platforms for branding and customization.

- Distributors: Decision depends on margin structure, supply chain control, and volume needs.

- DTC Brands Planning Scale: Chinese OEMs enable both customization and cost efficiency, giving brands control over design and profitability.

You might find our detailed litter box cost & ROI comparison guide helpful for understanding the financial impact of each option.

Why Early Positioning Matters for Private Label Growth

Knowing where your brand fits in the ecosystem is essential for long-term success. Early engagement with self-cleaning litter box manufacturers helps private label brands:

- Take control of firmware updates and features

- Iterate designs to meet user needs and market trends

- Align with global compliance requirements before scaling

For guidance on selecting the right manufacturing partner, you can reference choosing the right litter box manufacturer to ensure your private-label strategy starts on solid ground.

Litter Robot Cost vs China Manufacturers: Understanding the True Landed Cost

Landed Cost Breakdown for Litter Robot vs Chinese Litter Box Manufacturers

When assessing whether Litter Robot is worth it for importers, it’s important to consider more than the MSRP. Key cost components include:

- Manufacturing cost

- Shipping and customs duties

- Warehousing and distribution

- MOQ and tooling amortization

In contrast, the landed cost of automatic litter box from China tends to be more predictable, allowing private-label brands to maintain healthier margins and control cash flow.

Key considerations for landed cost:

- Tariffs, logistics, and compliance fees

- International transport and insurance, which can influence the final landed cost even if tariffs represent only a fraction of the total (OECD, 2025)

MOQ, Tooling Amortization, and ROI Implications

The ROI comparison litter robot vs Chinese manufacturers highlights different advantages:

- Litter Robot: Premium brand recognition, but lower operational flexibility

- Chinese OEMs: Scalable margins and cost-efficient production

Proper amortization of tooling costs can make private-label imports significantly more profitable, especially when planning multiple product SKUs or design iterations.

Margin Scalability for Private Label Importers

High-volume brands benefit from understanding automatic litter box profit margin OEM, which ensures sustainable profitability while maintaining product quality and customer satisfaction.

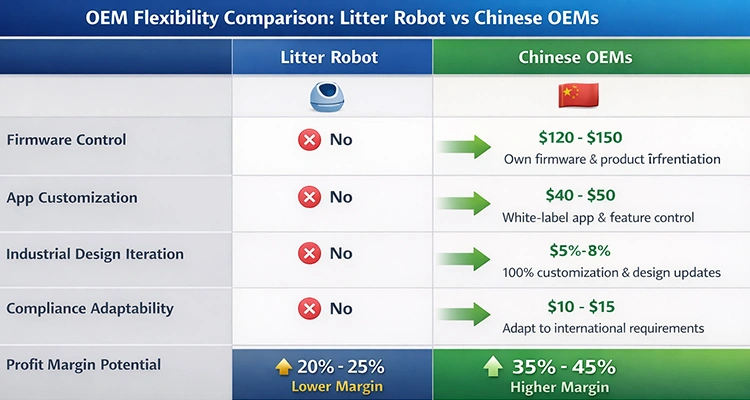

OEM Flexibility: Why Chinese Manufacturers Offer More Strategic Options

Firmware Ownership & App Customization

Litter Robot is a finished product, limiting control over firmware updates and app functionality. In contrast, Chinese OEMs provide:

- Ownership of firmware and updates

- App customization tailored to your brand

- Strategic flexibility for differentiation

Benefits include:

- Distinguishing your brand in a competitive smart litter box market

- Enhancing user engagement and usability, supported by research from the Association for Computing Machinery

For a detailed overview of customization options, you might find OEM & ODM smart litter box options helpful.

Industrial Design Iteration & Compliance Adaptability

Partnering with Chinese manufacturers allows brands to:

- Iterate industrial design efficiently

- Integrate new sensor and connectivity technologies

- Meet compliance & certification standards across global markets

For insights on certified facilities, CE-certified smart litter box factories provide reliable references.

Private Label Roadmap & Scale Potential

Working directly with factories gives brands:

- Factory direct manufacturing for stable supply chains

- Efficient response to evolving market demands

- Flexibility to optimize design, branding, and MOQ

For actionable guidance on these processes, you can refer to custom smart litter box factory guide.

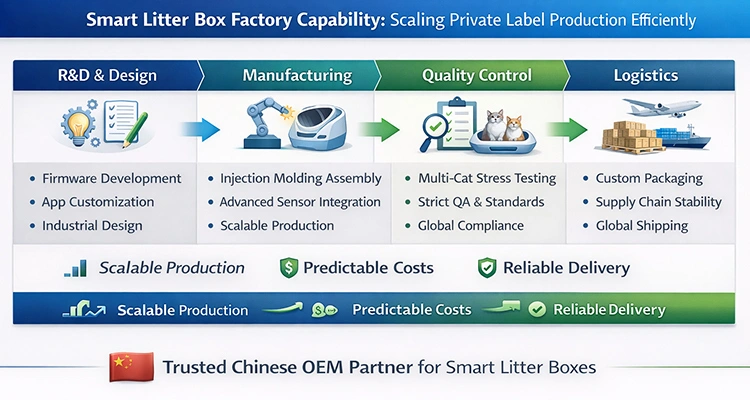

Scalable Automatic Litter Box Manufacturing: Engineering & Multi-Cat Testing Insights

Engineering Iteration Cycles & Multi-Cat Stress Testing

Leading Chinese OEMs implement rigorous quality control & testing to ensure products meet real-world demands, including:

- Multi-cat stress tests

- Rapid engineering iteration cycles

Multi-cat stress testing evaluates real-world durability under conditions that reflect actual household usage.

A 2025 peer-reviewed study in the Journal of Applied Animal Welfare Science highlights that multi-animal testing uncovers more failure points than single-animal testing, providing insights that standard lab testing often misses.

You might find the multi-cat reliability testing insights helpful when comparing potential OEM partners for private-label production.

Failure Rate at Scale & Quality Control Practices

For smart buyers, it’s crucial to assess how to evaluate Chinese litter box manufacturers and their ability to sustain low failure rates when scaling production.

A manufacturer’s quality control protocols—ranging from batch inspections to stress testing—directly impact your brand reputation and customer satisfaction.

Smart Litter Box Factory Capabilities

Top-tier factories offer access to:

- Advanced manufacturing technologies

- Robust supply chain management

- Efficient scale-up processes for private-label operations

You can learn more about OEM smart litter box engineering capabilities to gauge whether a manufacturer can meet your technical and production requirements.

Automatic Litter Box Warranty Comparison & After-Sales Support from OEM Manufacturers

Spare Parts Supply & SLA

Warranty coverage and availability of spare parts are critical to maintaining brand trust.

Many Chinese OEMs provide structured service-level agreements and maintain a reliable spare parts supply litter box factory, ensuring that your private-label brand can quickly respond to customer needs.

You might find the litter box warranty & after-sales comparison guide helpful when evaluating different manufacturing partners.

Return Risk & Brand Protection Considerations

Understanding risks of sourcing automatic litter boxes from China allows buyers to proactively protect brand reputation and minimize potential losses.

Return policies, spare parts access, and after-sales responsiveness are key factors in long-term importer satisfaction.

According to the World Bank’s Logistics Performance Index project (2025), after-sales support and supply chain resilience rank among the top determinants of repeat business for international buyers.

Making the Right Choice in 2026: Litter Robot vs Chinese Automatic Litter Box Manufacturers

When Litter Robot Makes Sense

- Direct-to-consumer brands prioritizing instant brand recognition

- Businesses willing to accept higher costs for minimal operational involvement

When Chinese OEMs Make Sense

- Private-label pet product brands looking to scale efficiently

- Companies seeking best litter robot alternative manufacturers with full customization and cost control

Common Buyer Mistakes & How to Avoid Them

A common pitfall is neglecting thorough due diligence on Chinese automatic litter box manufacturers. According to the OECD International Transport & Insurance Costs database (ITIC), careful analysis of freight, insurance, and customs impacts is essential to reduce procurement risks.

For actionable guidance, you can reference the smart litter box factory audit checklist, which helps ensure quality, reliability, and operational alignment before placing large orders.

Next Steps for Global Buyers: Audit, Cost, and OEM Flexibility Clusters

Factory Audit Checklist for Smart Litter Boxes

Global buyers benefit from following a litter box factory audit checklist that covers:

- Production capacity, QA systems, and compliance certification

- Equipment and tooling adequacy for high-volume orders

- Staff expertise in firmware integration, app-enabled features, and multi-cat stress testing

- Risk management procedures and contingency planning

A structured audit ensures you understand not just the factory’s capabilities today, but its ability to reliably scale as your private-label line grows.

Cost & ROI Analysis Cluster

A thorough evaluation of automatic litter box manufacturing cost and ROI scenarios helps determine which sourcing path makes sense

You might find litter box cost & ROI comparison guide helpful for comparing upfront investment, landed cost, and long-term profitability across different options.

OEM Flexibility Insights Cluster

Assess the OEM’s ability to support long-term brand growth, including:

- Private label pet products customization

- Firmware control and app customization to ensure long-term brand growth

- Industrial design iterations and packaging flexibility

- Scalability for future product expansions

These insights help ensure your chosen partner can adapt to evolving market trends without compromising quality or operational efficiency.

Trusted Chinese OEM/ODM Partner Spotlight: Petrust®

Why Petrust® Stands Out for Smart Cat Litter Box Brands

For global buyers, Petrust® combines smart litter box factory capabilities with flexible OEM/ODM manufacturing, providing both reliability and innovation.

Key Highlights:

- 12+ years of industry experience

- 230,000㎡ production facility

- High-volume factory direct manufacturing

- In-house R&D & engineering: firmware, app customization, multi-cat stress testing

Real-World Results:

- Average production cycle shortened by 15% versus the industry average

- Return rate reduced to 1.2% for multi-cat homes

- Private label clients have scaled up to 10,000 units/month with consistent quality

End-to-End OEM/ODM Services:

- Custom design & branding

- Packaging & logistics

- Supply chain stability & predictable profit margins

By partnering with Petrust®, brands gain a combination of reliability, flexibility, and innovation—meeting or exceeding Litter Robot standards while fully leveraging OEM potential.

You might find it helpful to request a personalized quote to understand how Petrust® can support your 2026 smart litter box plans.

Key Takeaways for Litter Robot vs Chinese Automatic Litter Box Manufacturers Decisions

- Cost vs Brand Premium: Litter Robot delivers brand equity; Chinese OEMs allow controllable landed costs

- OEM Flexibility: Ownership of firmware, app customization, industrial design iterations

- Manufacturing Reality & Risk Control: Evaluate factory capabilities, QC processes, supply chain stability, and after-sales support

Strategic due diligence—combining factory audits, ROI scenarios, and OEM assessments—positions global buyers for scalable automatic litter box production and private label smart litter box 2026 success.

With the right partner, you can balance cost, quality, and innovation to deliver market-ready products that satisfy both pets and owners.