For global brands and overseas buyers, partnering with a trustworthy Chinese OEM factory can be the difference between steady growth and constant supply headaches. Many businesses know the frustration of facing sudden price hikes, unexpected quality drops, or supply disruptions that threaten deadlines and customer satisfaction.

Building a dependable relationship with the right manufacturer doesn’t happen by chance. This guide shares actionable strategies and practical tips for forming a long-term, stable partnership with a Chinese OEM factory, allowing you to lock in costs, maintain consistent quality, and reduce the risks of supply chain volatility.

Along the way, you’ll gain insights into how experienced suppliers like Petrust® support international buyers with OEM/ODM smart pet product solutions, combining advanced R&D capabilities with scalable production.

By applying these best practices, you can confidently navigate the complexities of international sourcing, make informed decisions, and create sustainable growth that strengthens both your brand and your customer trust.

Section 1: Chinese OEM Factory Pricing Stability

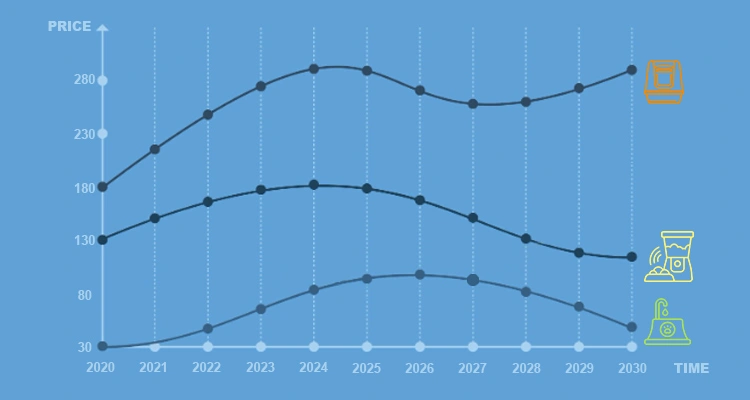

Keeping costs predictable is one of the most important challenges when working with a Chinese OEM factory. Even modest price increases can ripple through your budget, impacting profit margins and delivery schedules.

Many overseas buyers find that having a clear plan for price stability not only protects finances but also strengthens trust with manufacturing partners. You might find it helpful to reference the Chinese OEM Pricing Guide 2025: Proven Strategies to Keep Costs Stable & Predictable for a deeper dive into actionable approaches.

Understanding Price Fluctuations in Chinese OEM Factories

Price changes are often influenced by a variety of factors—raw material costs, labor rates, and currency fluctuations are common triggers. Additionally, Chinese OEM factories may adjust their pricing due to shifts in market demand or operational cost increases.

Recognizing these drivers early allows you to negotiate more confidently and plan ahead. Integrating cost forecasting and ongoing market trend analysis into your workflow can be especially helpful and is a key component of a Chinese OEM factory audit checklist.

Related Article >> Why China OEM Prices Increase Over Time & How to Prevent It

Locking Long-Term Manufacturing Costs

Establishing predictable costs requires more than just a signed contract—it involves strategic agreements and proactive planning. Long-term contracts with clear terms, coupled with detailed OEM cost control methods, help prevent unexpected charges and hidden fees.

Comparing multiple factory quotes and carefully evaluating potential cost traps ensures a realistic understanding of total production expenses. By applying these approaches, you can support cost-effective OEM manufacturing in China while reducing financial risks and building a foundation for reliable, long-term production.

Related Article >> How to Lock Long-Term Manufacturing Costs with Chinese OEM Suppliers

Negotiating Multi-Year OEM Contracts

Multi-year agreements create a foundation of trust and stability between you and your manufacturer. Focusing on multi-year OEM contracts in China can give you greater confidence in pricing, material sourcing, and delivery timelines. These contracts typically include clauses for price adjustments, payment terms, and handling material cost fluctuations.

A thoughtfully negotiated agreement encourages your Chinese OEM factory to prioritize your orders while maintaining fairness for both parties over time. You might also find tips from How to Negotiate with Chinese Pet Product Manufacturers for Better Pricing & Terms helpful in refining your approach.

Tip: Requesting a sample audit plan before signing a multi-year contract can align expectations on quality and costs, helping prevent surprises during mass production.

Related Article >> Negotiation Strategy for Multi-Year OEM Contracts in China

Related Article >> Hidden Cost Traps to Avoid When Working with Chinese OEM Suppliers

Cost-Effective Strategies for Stable Pricing

Price stability often comes from a combination of proactive planning and smart sourcing decisions. Diversifying suppliers, evaluating alternative materials, and accurately forecasting demand can all reduce unexpected cost spikes.

Implementing a structured OEM pricing strategy gives you more predictability, while incorporating insights from production capacity planning ensures that operations remain smooth, even during seasonal peaks or sudden market shifts. These steps help you maintain profitability without compromising quality or supply reliability.

Related Article >> China Material Cost Trends 2025: How It Impacts OEM Pricing

Related Article >> How to Compare Quotes from Multiple OEM Factories (Real Cost Breakdown)

Section 2: OEM Quality Stability

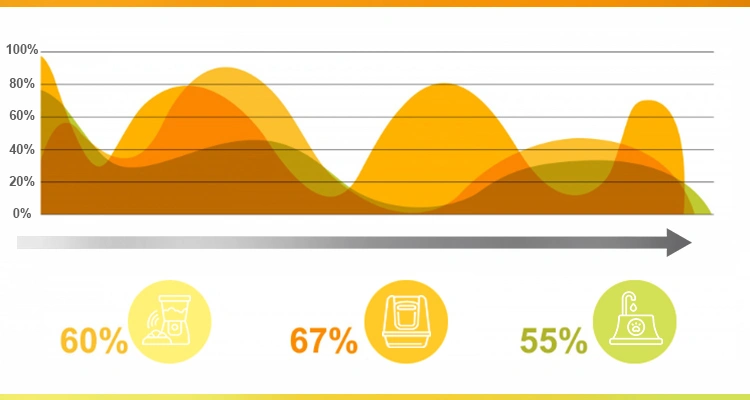

Ensuring consistent quality across every batch is just as important as meeting production timelines. A strong quality management system, combined with rigorous inspections, helps your products perform reliably year after year.

You can find additional insights in the Chinese OEM Quality Control: How to Build a Long-Term, Stable Manufacturing System in 2025, which provides practical steps for sustaining high standards.

Preventing Quality Fade in Chinese OEM Factory Partnerships

Starting with a trustworthy Chinese OEM factory lays the foundation for stable product quality. Frequent quality audits, clearly defined specifications, and open communication channels are essential for preventing quality fade in OEM partnerships.

For overseas buyers, tracking key quality indicators throughout the manufacturing lifecycle and monitoring production processes can make a tangible difference in maintaining consistent outcomes.

Related Article >> How to Prevent Quality Fade After Year 1 When Working with Chinese Factories

Establishing a Robust OEM Quality Control System

A well-structured OEM quality control system combines internal factory audits, in-line inspections, and third-party testing to safeguard product consistency.

Following a detailed Chinese OEM factory audit checklist helps ensure that every production run meets your standards. You might find scheduling periodic review sessions especially helpful for catching potential quality issues early and preserving long-term product quality.

Tip: Consider running a trial production batch to validate the effectiveness of your quality control procedures before committing to larger orders, giving you confidence in both the process and the final products.

Related Article >> Long-Term Quality Control Systems for OEM Manufacturing in China

Long-Term Product Quality Management

Sustaining product excellence requires proactive strategies, such as maintaining a dual supplier strategy, monitoring production processes closely, and applying structured lifecycle management. These measures help reduce the risks of inconsistencies and ensure your brand maintains a strong reputation in the market.

For guidance on aligning your production approach with your business goals, you can refer to Pet Product OEM vs ODM Explained: Which Model Fits Your Business? to decide which model works best for your needs.

Related Article >> How to Maintain Stable Product Quality Over Years (OEM Quality System 101)

Related Article >> Factory Audits & Re-Audits: How Often Should Buyers Inspect?

Best Practices for Overseas Buyers

For overseas buyers, quality stability isn’t just about factory capability—it’s about engagement. Regular on-site or remote factory visits, clear communication checkpoints, and consistent reporting are key.

Leveraging manufacturing quality control methods alongside proactive factory visit and inspection tips can help you catch potential issues early, maintain high standards, and foster a long-term partnership that benefits both your brand and your supplier.

Related Article >> Best QC Processes for Overseas Buyers Working with OEM Factories

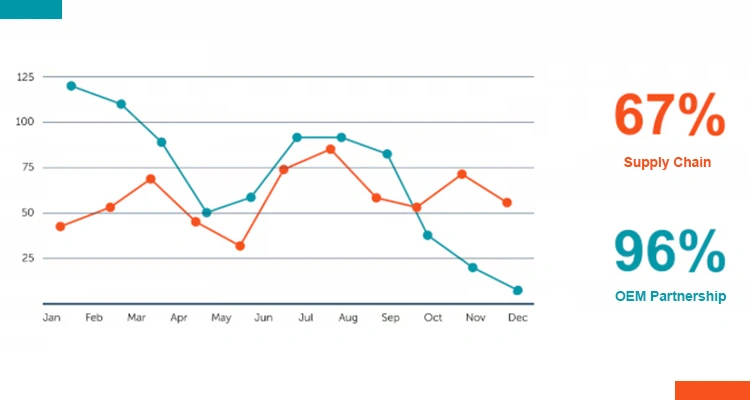

Section 3: OEM Partnership & Supply Chain Stability

A strong partnership and a resilient supply chain are the backbone of long-term success. Working with a Chinese OEM factory goes beyond production capacity—it means collaborating with a partner who understands your business priorities and is committed to supporting your supply chain.

You might find the strategies in the OEM Supply Chain China (2025 Playbook): A Proven Framework for Building Stable, Long-Term OEM Partnerships for strengthening this collaboration.

Recent studies indicate that manufacturers investing in supply chain resilience and nurturing long-term supplier relationships tend to achieve higher operational stability and productivity over time (Manufacturing Supply Chain Resilience Amid Global Value Chain Reconfiguration: An Enhanced Bibliometric–Systematic Literature Review, 2025, Systems).

These insights highlight why cultivating a dependable OEM relationship is not just a transactional step, but a strategic investment in your brand’s future.

Building a Long-Term Relationship with Chinese OEM Factory

Trust forms the foundation of any enduring partnership. Transparent agreements, consistent communication, and aligned business goals help establish a relationship with a Chinese OEM factory that grows stronger over time.

A dependable partner can offer long-term OEM manufacturing agreements and prioritize your production needs, which is especially valuable for brands aiming for steady market expansion. You can also leverage regular performance reviews and collaborative planning sessions to keep the partnership aligned with evolving business objectives.

Related Article >> How to Build a Reliable Long-Term Relationship with Chinese OEM Factories

Ensuring Priority Production and Better Lead Time

Securing priority production slots and monitoring lead times is crucial for maintaining a competitive edge. Working closely with reliable Chinese suppliers allows you to coordinate scheduling effectively, ensuring your orders are delivered on time—even during peak seasons or unforeseen global disruptions.

Evidence from recent supply chain studies in China shows that factories with robust resilience frameworks are far more likely to maintain on-time delivery and minimize disruptions (Analysis of manufacturing supply chain resilience in China, 2024, Procedia Computer Science).

By proactively managing production priorities with your OEM partner, you safeguard both your supply chain and your brand reputation.

Related Article >> How to Get Priority Production & Better Lead Time from Chinese Suppliers

Related Article >> How to Ensure Stable Production Capacity During Peak Seasons

Mitigating Supply Chain Risks

Unexpected supply chain disruptions can create ripple effects, delaying deliveries, inflating costs, and challenging your brand’s reliability. Applying supply chain risk management strategies—such as contingency planning, diversifying supplier sources, and monitoring logistics performance—can help maintain steady production and protect your timelines.

You might find it helpful to reference studies on enhanced supply chain transparency, which show it can significantly reduce crash-risk and buffer businesses against sudden market shocks when collaborating with overseas partners (Managing crash risks through supply chain transparency: evidence from China, 2024, Financial Innovation).

These practices not only safeguard your operations but also give you peace of mind when scaling with a Chinese OEM factory.

Related Article >> How to Avoid Supply Chain Disruptions When Manufacturing in China

Protecting Your IP and Product Design

When working with overseas manufacturers, protecting your intellectual property is as important as ensuring product quality. Clearly defined contracts, confidentiality agreements, and robust IP protection measures help ensure that your designs, proprietary processes, and innovations remain secure while partnering with a Chinese OEM factory.

You can also implement phased sharing of technical files or utilize trusted third-party audits to reinforce your protections—approaches that many global brands find helpful in building long-term, worry-free partnerships.

Related Article >> How to Protect Your IP and Product Design When Working with OEM Factories

Related Article >> How to Evaluate Communication Quality with Chinese OEM Teams

Ensure Long-Term Success With a Reliable Chinese OEM Factory

Building a strong, lasting partnership with a Chinese OEM factory goes beyond negotiating the lowest price—it’s about balancing cost, quality, and supply chain reliability. By establishing long-term agreements, implementing thorough quality control systems, and proactively managing risks, B2B buyers can enjoy consistent production, predictable costs, and peace of mind knowing their supply chain is stable.

Working with Petrust® brings additional benefits that make scaling your brand smoother. You can rely on rapid responses to production adjustments, fully customizable OEM solutions, and more than a decade of proven experience supporting global brands in smart pet products. These capabilities help ensure your product launches stay on schedule and meet quality expectations.

You might find it helpful to reach out and discuss your specific production goals with Petrust®. Strong partnerships like these not only protect your brand’s reputation but also set the foundation for sustainable growth and long-term profitability.

Contact Petrust® today to review your production needs and explore how a reliable OEM collaboration can help your brand thrive.