What really goes wrong when smart feeder OEM mass production trips up even after flawless sample approvals? Many brand owners, procurement managers, and product managers have faced the frustration: the pilot runs work perfectly, but as soon as the order scales, subtle flaws emerge—flaws that were invisible in the carefully controlled sample phase.

This gap isn’t accidental. It reflects a predictable challenge: moving from prototype to full-scale production introduces new stresses across components, assembly, firmware, and quality verification. Recognizing this early can save months of rework, prevent compliance risks, and protect your brand reputation before the first large batch ships.

In today’s competitive pet tech market, passing samples ≠ production readiness. What works for a handful of units doesn’t automatically translate to thousands. The distinction between pilot run vs mass production is where most hidden costs arise, from component tolerances to sensor sensitivity and process drift.

Brands that take the time to identify scale-specific risks early often save substantial time, costs, and headaches down the line.

– Key Takeaways –

- Passing samples ≠ production readiness

- Pilot run vs mass production issues often emerge later

- Early recognition of scale-specific risks saves time and cost

This Article Is Not About Failure — It’s About How OEM Decisions Are Usually Misjudged

This article isn’t another technical guide on quality control or a critique of manufacturers. Its purpose is to mirror your decision-making process back to you. Many teams equate passed testing with a reliable OEM partner, yet this assumption can quietly lay the groundwork for challenges later.

The moment a team thinks “everything looks fine” is often the moment hidden risks begin to accumulate. Understanding this can help you approach smart feeder OEM mass production with clarity rather than optimism alone.

The Hidden Starting Point of Smart Feeder OEM Mass Production Failures

Production failures rarely happen out of nowhere. They are often seeded in the judgment calls made immediately after sample approval. A WiFi-enabled smart feeder may perform perfectly in isolated tests, and an app-controlled pet feeder might operate flawlessly in a pilot run—but scaling exposes variables that were invisible during these early stages.

For a deeper perspective on long-term partnerships and why some manufacturers succeed while others falter, insights on smart feeder OEM partnerships provides a strong industry lens on this issue.

Why Passing Samples Feels Like Progress — But Often Isn’t

Seeing prototypes work flawlessly can create a false sense of confidence. Cognitive biases, sunk cost considerations, and overconfidence can lead teams to overlook subtle but critical differences between controlled pilot runs and full-scale operations. Minor deviations that seemed negligible in small batches can compound when production volumes increase.

For those who want technical precision, factors affecting feeder accuracy in real use offers a deeper dive into the practical elements that influence performance in the field.

– Mini Case Example –

A client’s WiFi feeder project sailed through sample testing without a single defect. However, once 10,000 units were produced, minor motor torque inconsistencies led to a 5% defect rate—illustrating how scaling can reveal risks invisible during early validation.

Process vs Prototype: Why Samples Are “Protected,” but Production Is Exposed

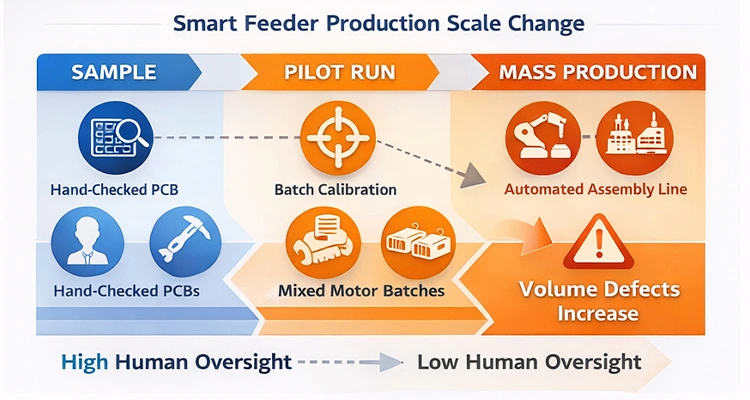

Samples are inherently curated. Engineers handpick components, tweak firmware, and calibrate sensors individually. Moving from pilot run vs mass production, these meticulous interventions disappear, leaving room for variation that can disrupt consistency.

Smart Feeder Prototype vs Production: What Actually Changes at Scale

| Sample Stage | Mass Production Stage |

| Feeder PCB design hand-checked | Automated assembly line |

| Manual sensor calibration | Batch calibration |

| Selected motors with perfect torque consistency | Mixed motor batches |

| Controlled environment | Multiple factories, shifts, supplier variations |

These invisible changes during the sample phase often become the root cause of volume production defects. For actionable insights on preventing jams and other issues during scaling, practical anti-jam strategies for smart feeders can be highly informative.

OEM Sample Approval vs Mass Production: The Illusion of Control

Approving a single prototype is never a guarantee. Teams frequently discover that what works in samples can fail in mass production, especially when firmware stability across batches and BOM change at scale are not rigorously validated.

A structured overview of manufacturing steps, such as the step-by-step OEM production workflow, helps illuminate where these hidden risks most often emerge.

As highlighted in the 2024 National Academies report on smart manufacturing systems, inconsistent calibration and data recording during the transition to large-scale production can introduce quality control uncertainty. This underlines why passing samples alone does not equate to production readiness—you can reference this study for modern strategies to maintain consistency at scale.

Systemic Risks That Only Appear During Smart Feeder OEM Mass Production and How to Mitigate Them

Problems that emerge during scaling are rarely isolated technical glitches—they reflect systemic risks amplified by complexity. In modern manufacturing environments, maintaining product quality and consistency at scale is inherently challenging.

Research in Journal of Intelligent Manufacturing on “Quality 4.0” shows that advanced process monitoring, real-time feedback, and continuous verification are critical to manage risks that only appear during large-scale production. You might find this study helpful for understanding how industry leaders approach smart feeder OEM mass production quality challenges.

– Key Takeaways –

- Systemic risks increase exponentially with scale

- Advanced monitoring and process feedback help mitigate defects

- Proactive identification of workflow risks is critical

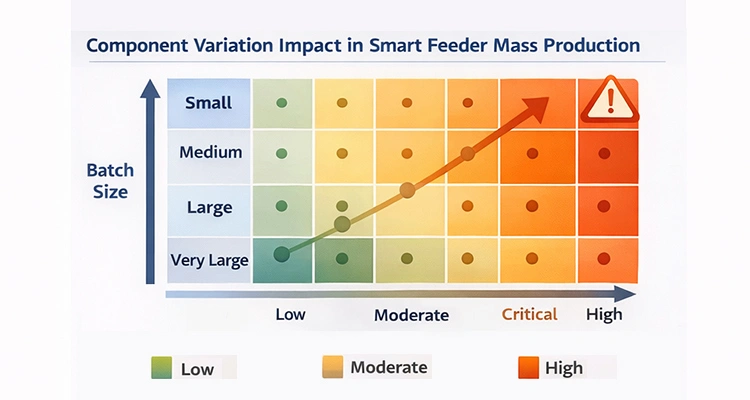

Component Variation and Batch Consistency in Electronic Feeders in Smart Pet Feeder Mass Production

Even minor differences in load cell accuracy, resistor tolerances, or capacitor batches can create measurable inconsistencies. Unexpected defects after volume orders are frequently traced back to overlooked component-level variation or subtle supplier substitution risk.

Studies on manufacturing systems highlight how multilayered operational variations accumulate in complex processes, degrading overall product reliability.

For importers, understanding component variation and batch consistency is a practical way to anticipate pitfalls during smart feeder OEM mass production. You can also reference guide to safe materials in smart feeders to ensure compliance and safe component selection.

OEM Production Handoff Issues No Sample Test Can Reveal

Workflow transitions—between engineering, manufacturing, and QA teams—can introduce errors invisible during sample testing. Gaps in documentation, tooling differences, or misaligned responsibilities can result in quality dropped after mass production, even when initial samples performed flawlessly.

Using a pre-shipment quality checklist for smart feeders helps teams catch these gaps before products leave the factory, translating lessons from prototypes into reliable mass production outcomes.

The Ownership Gap: When Everyone Assumes “Someone Else” Is Responsible

Scaling exposes a subtle but critical challenge: who truly owns product quality?

Who Actually Owns Quality During Smart Feeder OEM Mass Production?

Responsibility diffusion is surprisingly common. Engineering assumes QA will catch deviations, QA relies on production SOPs, and procurement assumes the batch has been validated.

During smart feeder OEM mass production, this ownership gap becomes highly visible—and when systemic issues occur, the brand often absorbs the consequences.

For guidance on aligning accountability and app management, post-production app ownership considerations offers practical insights. To clarify responsibility under different contractual frameworks, OEM vs ODM business model guidance explains how ownership and accountability should be structured from day one.

– Bullet Summary –

- Responsibility diffusion is common

- Clear cross-functional ownership reduces scale risk

- Post-production accountability must be defined early

Who Absorbs the Cost When Smart Feeder OEM Mass Production Fails?

Failures at scale extend far beyond the factory floor, carrying real strategic implications.

The Real Cost of OEM Mass Production Failure After Launch

Costs go well beyond contract manufacturing for smart feeders:

- Customer complaints and returns

- Platform ratings and retailer trust

- Delays in new product launches or market expansion

- Reputation damage affecting future investment

Even projects that passed testing but failed after launch demonstrate that the financial and strategic burden often falls on the brand rather than the factory.

You might find comprehensive smart feeder manufacturing insights helpful to understand the broader workflow, scalability considerations, and cost implications before committing to a large-scale OEM partnership.

Why Most OEM Evaluations Fail Before Production Even Starts

One of the most overlooked realities in pet tech manufacturing is that traditional evaluation metrics—sample performance, small pilot runs, and initial QA checks—rarely reveal whether a manufacturer can scale reliably.

Many brands assume that early success guarantees mass production consistency, only to face unexpected issues once the order volume grows.

Rethinking Evaluation Criteria for Smart Feeder OEM Mass Production

Evaluation must go beyond surface-level checks and anticipate challenges unique to large-scale manufacturing. Key considerations include:

- OEM engineering validation for batch variability

- Tooling validation stage to ensure reproducible quality

- Anticipating issues only appear after scaling

- Checking for electronic feeder batch consistency issues

Without incorporating these elements, your assessment focuses on the wrong capabilities—leaving scalability risks unaddressed. You might find it helpful to consult methods to verify smart feeder suppliers, which provides step-by-step guidance for independently validating manufacturer reliability before production begins.

What Long-Term Smart Feeder OEM Mass Production Partners Get Right Early On

Successful OEM partnerships understand that scaling is not simply repeating the prototype—it’s entering a new phase where every unit must perform reliably. Top partners design systems and processes to maintain consistency across batches, integrating cross-functional ownership from day one.

From Sample Success to Scalable Systems: The Missing Perspective

High-performing OEM collaborations focus on:

- Consistent feeder OEM manufacturing system practices

- Strong OEM mass production workflow management

- Predictable smart feeder production consistency across factories

For brands evaluating long-term scalability, the sample-to-scale evaluation workflow provides context on connecting early sample success to reproducible mass production outcomes.

– Mini Takeaway –

- Scaling successfully isn’t about passing samples alone—it’s about replicable systems, clear ownership, and proactive process design.

Conclusion

Passing samples is not the finish line—it’s the point where true risk begins. The transition from small-scale pilot to smart feeder OEM mass production is where judgment, process rigor, and ownership structures are truly tested.

The higher-order question every brand should ask is:

“If OEM performance at scale is the real measure, are your evaluation methods truly capturing the manufacturer’s ability to deliver consistent, high-quality units at volume?”

To ensure your smart feeder OEM scaling is safe, you might find our Smart Feeder OEM Quality Checklist helpful for pre-production evaluation. This proactive review helps you catch pilot run vs mass production issues before they affect thousands of units, providing peace of mind and protecting your brand’s reputation.