What does it really take to know how to choose a trusted litter box manufacturer when every decision could affect your brand’s reputation, delivery schedule, and bottom line?

You approved the sample.

It looked perfect—the motor ran smoothly, the plastics felt sturdy, and the factory’s team was confident, responsive, and seemingly ready for mass production.

Then production began—and suddenly, reality hit.

Motors started failing after just a few weeks, leading to a 15% return rate in the first month. Sensors acted inconsistently, delaying your launch by nearly three weeks. Plastic parts warped under real-world conditions. The factory explained it away as “normal tolerance,” while your market questioned your brand’s reliability.

In that moment, many importers face an uncomfortable truth:

- It wasn’t the litter box that failed.

- It was the choice of manufacturer.

This guide isn’t a list of suppliers. Instead, it’s a risk-avoidance framework for OEM buyers who want to understand how to choose a trusted litter box manufacturer before costly mistakes become irreversible. It addresses the common pitfalls, compliance risks, and hidden production challenges that often lurk behind seemingly flawless samples.

For a grounded perspective on reliable partnerships, you might find why long-term OEM partners choose Petrust® for trusted litter box manufacturing helpful—it highlights how proven processes and transparent collaboration can protect both your products and your brand.

Why Choosing a Trusted Litter Box Manufacturer Is Harder Than Most Buyers Expect

On paper, sourcing a litter box manufacturer seems straightforward.

In reality, global importing trips up even experienced buyers—not because options are scarce, but because the real risks are often invisible until it’s too late.

Every brand owner wants smooth production, consistent quality, and on-time delivery, yet hidden complexities quietly erode these goals. Understanding where these risks lie is the first step toward building reliable supply chains.

Why Most Litter Box Manufacturing Problems Appear After Sample Approval in OEM Projects

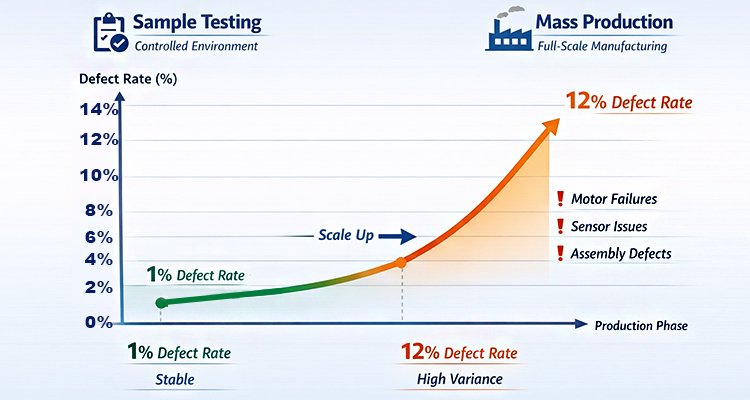

Samples rarely tell the full story of mass production.

During sampling, factories often assign senior technicians, manually tune components, or temporarily upgrade parts to secure approval. Once orders scale, these temporary safeguards disappear—sometimes revealing quality gaps that never showed up during sampling.

A 2024 study by the National Academies of Sciences, Engineering, and Medicine highlights how distributed manufacturing and scale-up challenges continue to create inconsistencies between prototype and mass production phases.

This explains why so many mass production quality issues litter box projects surface: motors that fail under full load, sensors that behave inconsistently, firmware bugs, or assembly variations that never appeared in samples.

Recognizing this gap is central to how to vet a litter box manufacturer effectively.

For deeper insight, you might find our analysis of first-order vs mass production challenges helpful to understand why early orders often succeed while scaled production falters.

The Hidden Costs of Choosing the Wrong Litter Box Manufacturer

Visible costs—like rework, delays, or scrapped units—are only part of the story. The hidden costs hit harder.

Missed launch windows. Distributor penalties. Erosion of brand trust. Emergency air shipments. Engineering resources diverted from growth to firefighting. Many importers only notice OEM litter box cost overruns after cash flow is stressed—sometimes exceeding 20% of the initial project budget.

The 2025 OECD Supply Chain Resilience Review highlights how upstream and downstream dependencies magnify exposure to production shocks, driving operational costs higher if not actively managed.

Global importing isn’t just about purchasing—it’s about deliberate risk allocation.

You might find common OEM risks importers face when sourcing from China helpful to understand how complications go beyond obvious costs.

Common “Trust Signals” That Mislead Global OEM Buyers

Many buyers rely on surface signals that feel reassuring—but rarely predict long-term production stability.

“10+ Years of Experience” Doesn’t Guarantee a Reliable Litter Box Manufacturer

Years in business concentrated in sales teams is not the same as deep manufacturing experience.

A truly reliable litter box manufacturer demonstrates engineering continuity, documented failure analysis, and controlled production feedback loops—not just age.

The key distinction lies in engineering capability vs trading company behavior, even when both present themselves as “factories.”

For smart litter boxes, considering what R&D capabilities matter when choosing a manufacturer can help differentiate suppliers who can scale successfully from those who cannot.

Why “CE / FCC Ready” Often Fails in Real Global Importing

Certificates alone cannot guarantee compliance.

Even minor component swaps can invalidate previous testing, and firmware updates can change emissions behavior. Static paperwork doesn’t protect importers from regulatory risk.

The World Manufacturing Report 2024 explains how technological, geopolitical, and regulatory pressures can render conventional certificates insufficient in dynamic production environments.

For guidance on compliance and safety, you can find CE certified litter box manufacturers a helpful reference for evaluating responsible suppliers.

Low MOQ Litter Box Suppliers: Convenience or OEM Risk for Global Importing

A low MOQ may feel safe—but often signals limited commitment.

Suppliers willing to accept minimal volumes frequently lack proper tooling investment, structured testing, or long-term support planning. In practice, this raises the likelihood of smart litter box manufacturing challenges emerging mid-project, jeopardizing timelines and product reliability.

What Buyers Often Overlook When Learning How to Choose a Trusted Litter Box Manufacturer

Most sourcing guides emphasize price or production capacity. Experienced importers know that real value lies in systems, not numbers.

Many buyers don’t see how their products will perform in the real world until it’s too late:

- Case 1: A small MOQ supplier couldn’t replace a critical motor fast enough, halting production for three weeks.

- Case 2: A “CE-ready” manufacturer swapped a sensor component last minute, resulting in a 12% failure rate after shipment.

- Case 3: A long-term partner lacked clear firmware update protocols, delaying deployment in multi-cat households.

Stories like these show why a structured evaluation process is not optional—it’s essential for protecting timelines, compliance, and brand credibility.

Why Trust in OEM Manufacturing Is a System, Not Just a Promise

Trust isn’t built on assurances; it’s built on repeatable systems and transparent processes.

A thorough litter box supplier due diligence process examines how decisions move through sales, engineering, quality control, and after-sales support. Without such systems, reliability becomes accidental rather than predictable.

The OECD Supply Chain Resilience Review emphasizes that governance, clarity, and accountability frameworks are vital for resilient global supplier relationships. You might find OEM vs ODM practices that build long-term trust helpful to understand how structured systems translate into dependable outcomes.

Sales, Engineering, QC, After-Sales: Where Trust Is Actually Created

In a mature litter box OEM manufacturer, these functions are independent but fully aligned. Clear boundaries define who owns failures, who approves changes, and how after-sales responsibilities are managed before shipment rather than negotiated under pressure later.

For a real-world example of how alignment supports reliable production, you can reference the Petrust® OEM process from concept to stable mass production, which illustrates step-by-step how systemic trust protects both brand and product quality.

How to Evaluate Litter Box Manufacturers for Global Importing Projects

Evaluation is most effective when it happens before pricing discussions, not after. Early insight allows you to identify hidden risks and avoid costly missteps. You might find our guide on evaluating litter box manufacturers for global importing projects helpful as a structured starting point.

Key Questions for Global Importing Supplier Assessment

Strong importers ask the hard questions early:

- Who owns tooling if the project stops?

- How are firmware updates validated?

- What data exists on field failure rates?

- How is spare parts supply consistency ensured?

These questions help distinguish casual suppliers from trusted OEM litter box supplier candidates capable of supporting growth and compliance over the long term.

Early Red Flags in Litter Box OEM Communication

Warning signs often appear in the first conversations: vague responses, overconfidence, or reluctance to share process details.

The NIST Quick‑Start Guide for Cybersecurity Supply Chain Risk Management shows that standardized risk assessment procedures provide clear visibility into multi-tier supplier ecosystems, helping buyers identify communication gaps and operational weaknesses early.

These patterns explain why many importers struggle when choosing pet product manufacturers in China without a structured evaluation model. For hands-on verification, you can refer to our guide on factory audit checklist for self-cleaning litter box buyers, which provides actionable steps to confirm a manufacturer’s capabilities and reliability before committing.

How to Choose a Trusted Litter Box Manufacturer Before Paying Any Deposit

This moment is critical—your last chance to control risk before money leaves your account. Choosing the right partner here can save weeks of delays, unexpected costs, and potential brand damage.

How to Choose a Trusted Litter Box Manufacturer Using Sample vs Mass Production Data

Promises are easy. Evidence is what matters.

Instead of relying solely on assurances, gather real data. Compare sample BOMs to mass-production BOMs. Review historical defect rates for motors and sensors, and check firmware stability across smart litter box versions.

This evidence-based approach shows whether the litter box quality control process is truly mature, or just polished for initial impressions.

Factory Audit vs Factory Visit: What Actually Matters

Factory visits can impress, but audits protect.

A meaningful audit focuses on traceability, tooling ownership for OEM projects, and the factory’s corrective-action history—not showroom polish or staged demo units. These details reveal whether the manufacturer can consistently deliver at scale.

Compliance Reality Check for Importing Litter Boxes into the US and EU

Compliance issues rarely appear at customs—they usually surface months after launch, when shipments are in the market and brand trust is at stake.

Why Certification Documents Alone Don’t Reduce Import Risk

Regulations evolve, components change, and suppliers often optimize costs quietly. Certification papers alone cannot guarantee safe, compliant shipments. Without continuous compliance management, importing litter boxes regulations can quickly become liabilities rather than safeguards.

You can review our guide on quality & compliance standards importers should expect to get a clear picture of global requirements.

Who Is Responsible When Compliance Fails After Shipment?

Recalls aren’t just costly—they spark disputes over responsibility.

Clear OEM contracts that define liability, testing scope, and cross-border warranty issues before production are essential. Waiting until after market exposure usually leads to disputes, lost revenue, and weakened brand reputation.

From Supplier to Partner: How to Choose a Trusted Litter Box Manufacturer for Long-Term OEM Success

When scaling your brand, the relationship you build often matters more than the unit price. A single misstep with the wrong manufacturer can ripple across shipments, certifications, and customer trust.

Many importers realize too late that selecting the right partner is less about the first order and more about long-term reliability, compliance, and growth.

How to Choose a Trusted Litter Box Manufacturer That Can Scale With Your Brand

A strong OEM partner does more than fulfill orders—they invest in documentation, failure prevention, and product lifecycle management. They anticipate problems before they appear, ask the difficult questions, and stay involved beyond the first shipment.

This kind of engagement ensures your product survives not just launch, but scaling across multiple SKUs and markets.

Supplier vs Manufacturer: Why the Difference Matters in OEM Projects

Suppliers coordinate; manufacturers commit. That distinction can determine whether a project thrives or collapses under complexity within global sourcing litter box manufacturers ecosystems.

A committed manufacturer like Petrust® takes ownership of engineering quality, component consistency, and regulatory compliance—protecting both your brand and your timeline.

A Practical Scorecard for Comparing Litter Box Manufacturers

Tools outperform intuition, especially when investment stakes are high.

Key Evaluation Criteria for Litter Box OEM Projects

A meaningful scorecard evaluates:

- Electronics reliability OEM data

- Historical motor failure rates

- Sensor defects litter box trends

- Engineering change discipline

This approach replaces guesswork with measurable comparison, letting you evaluate potential partners against hard metrics rather than promises alone.

Using This Scorecard to Choose a Trusted Litter Box Manufacturer Confidently

Applied consistently, the scorecard uncovers patterns that conversations and quotes alone often hide. It empowers rational decisions, even when some suppliers offer attractive pricing or rapid turnaround. Using such a tool helps ensure that your first order is just the start of a predictable, scalable partnership.

Conclusion

Think back to two importers approving nearly identical samples. One prioritized speed; the other prioritized structure and reliability.

The first importer faced delays, disputes, and brand erosion. The second importer built predictability, resilience, and long-term growth.

Most successful global importers don’t chase the fastest manufacturer. They choose safer partners, and then scale with confidence. By focusing on trust, consistency, and transparent processes, you set your litter box OEM projects up for success—long after the first shipment reaches the market.